Products

Laser Seam Tracking

Laser Seam Tracking is a non contact torch guidance system for welding automation. Laser Sensor is mounted in front of a welding torch on a SPM or Robot so the sensor looks at the weld joint ahead of welding to calculate and dynamically correct the torch position in realtime.

Line Tracking System

Line Tracking System is a non contact white line sensing and guidance system for ERW Pipe UT Testing. Special camera is mounted to the UT head to sense the centre of the white pilot line and the feedback is used to compensate for any deviation in the pipe position.

Weld Inspection

Weld Bead Inspection System measures the weld bead geometry such as Bead Width, Height, Toe angles, and compares it against the set limits to classify good or bad. It can also identify common weld defects such as Undercut, Concavity, Missing weld, Blow Holes etc...

Welding Cameras

KML Offers ruggedised high quality miniature video cameras to monitor welding stations remotely. These cameras are suitable for open arc, submerged arc welding and other general industrial use.

Laser Seam Finding

Laser Seam Finding is a non contact system to find the offset of the loaded component from the programmed path. Laser Sensor measures the joint prior to welding at one or more places to calculate the offset and the same is used to offset the taught path.

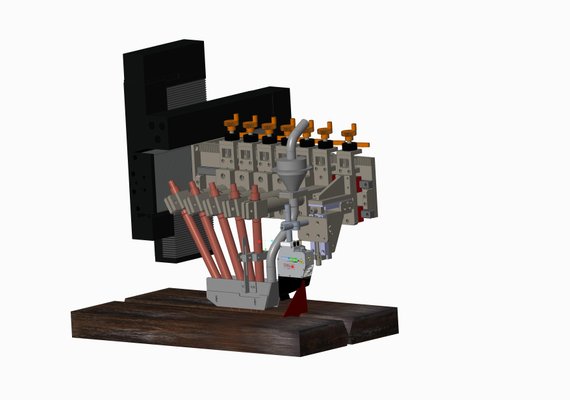

Pipe Mill Control System

KML Offers complete Pipe Mill control syetm including Welding Control, Sensor Control, IOT.

Pipe Inspection

Laser Pipe Dimensioning System is the most advanced Pipe Inspection system available in the market. System generates complete 3D model of the pipe and measures all the key parameters such as Inside Diameter, Outside Diameter, Wall Thickness, Straightness of the pipe, Ovality, Bevel Parameters, Length etc...

Adaptive Welding

KML Offers customised solution for heavy welding application where we can dynamically control the welding parameters so that any deviation during fit up is compensated. Auto Weld bead sequencing is also possible.