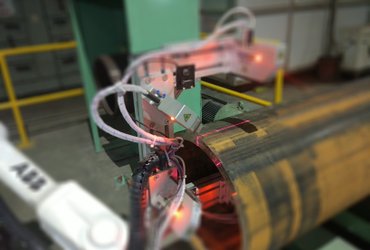

Laser Seam Tracking Systems for Welding Automation

India's First and Only Laser Sensor Company

KML Sensors designs and manufacture Laser Vision Systems for wide range of Welding and 3D inspection applications. Our Laser Sensors are desinged and made in India for the World. We use the most advanced technologies in our sensor system to withstand the harsh welding environment at the same time make inline precision measurements.

Products

Our Laser Sensors are used for Laser Seam Tracking, Joint Finding, Adaptive Welding, Dimensional Inspection, Pre / Post Weld Inscpection and many more...

Applications

Our Laser Sensors are used for wide range of applications. Aerospce, Automotive, Energy, Tube and Pipe, are some of our key applications

News

KML has signed a contract to supply a Complete Pipe Dimension Measurement System to an renowned ERW pipe manufacturer.

Revolutionizing Laser Seam Tracking.

Providing cutting-edge sensor technology and data management solutions for welding automation.

Weld with Precision and Confidence.

Our innovative laser tracking system ensures precise and reliable seam welding, every time.

Advantages

Achieve Perfect Welds Every Time.

Our Laser Sensors provide precise guidance for welding machines and robots, ensuring accurate and consistent welds.

Increased Efficiency.

With Laser Sensors you can streamline your welding process and reduce downtime. The system's real-time monitoring ensures consistent weld quality, minimizing the need for rework.

Improved safety.

Laser Seam Tracking reduces the risk of errors and accidents during the welding process. The system's precise guidance minimizes the need for manual adjustments, keeping your workers safe.

SIGN UP FOR OUR NEWSLETTER

Want to Keep Up to Date with our Latest News and Information?

Enter your Email Address below to be added to our mailing list